Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

When an Armenian manufacturer managing a Russian factory needed to cut 13mm aluminum tubes with surgical precision, they turned to global suppliers. Here's why we became their final choice – and what it means for your next project.

The Puzzle

The challenge is cutting 41 pcs micro-tubes (Ø10mm, 1mm thickness) in a single pass without compromising speed or surface finish.

Our Playbook

Speed Meets ScienceWithin 48 hours of initial inquiry, we delivered a customized solution: a multi-laser array system with vibration-dampening fixtures. No generic proposals – just engineered answers.

Proof Before Payment

When the client sent 100 sample tubes, we didn’t just run tests – we filmed a live demo video showing:

The Trust Builder

The customer said:”You are the best in communication with customers! I have contacted several companies, but insist to order from your company, even we had cheaper offers, only because of you and my belief that your company placed quality the first.”

The Verdict

"You’re not buying machines, and you re buying peace of mind if you choose SteviS."

Your Turn to Upgrade

Whether you’re cutting aerospace micro-tubes or architectural beams, our philosophy remains:Your problem becomes our R&D blueprint until it’s solved.

A prominent furniture manufacturer in Poland, specializing in high-quality sofa feet and metal furniture components, sought to upgrade their welding capabilities. Their production involved various designs and small batches, requiring a solution that was not only compact and easy-to-use for manual operation but also capable of seamless integration with collaborative robots (cobots) for automated welding stations. They needed a versatile system to enhance flexibility and throughput without compromising on weld quality for their diverse product range.

Understanding the dual need for manual welding flexibility and cobot cell compatibility, we recommended the SteviS 1.5KW Handheld Laser Welder. Its robust industrial performance and adaptable design made it an ideal fit. Furthermore, as a manufacturer, we provided an additional layer of customization to meet their specific branding and workshop needs.

"The SteviS welder's versatility for both hand-held and robotic use was exactly what we needed. The fact that we could get it in our company color was an unexpected and excellent service that showed their customer-centric approach."

- Production Manager from Polish Furniture Manufacturer

In the highly demanding world of heavy-duty construction shoring and scaffolding, one of European most respected manufacturers (with over 50 years of experience and exports to more than 54 countries) , which is located in Italy, needs to dramatically increase cutting speed and precision while maintaining the strictest European quality and safety standards.

Traditional pipe-cutting methods were becoming the bottleneck: slow cycle times, inconsistent accuracy, and excessive material waste were threatening the company's ability to meet growing international demand on time.

The solution: our latest-generation 6 kW fiber laser pipe cutting system equipped with a 7.5-meter fully automatic loading rack.

Why this machine was the perfect fit?

Real results achieved in daily production

Production Manager of the company comments: “Switching to this 6 kW automatic laser system has completely transformed our scaffolding tube preparation line. The 7.5-meter loading rack runs unattended for hours, delivering perfect cuts every time. We’re now able to take on larger contracts and shorter lead times without compromising the quality our customers expect from us.”

Ready to eliminate your own production bottlenecks?

If you manufacture scaffolding, post shores, modular framing, or any high-volume tubular products, the same technology that revolutionized this European leader’s factory can do the same for you.

Contact us today for a free consultation or live demonstration of the 6 kW fiber laser pipe cutter with fully automatic 7.5-meter loading system.Let’s cut faster, waste less, and grow together.

When a construction company from Moldova needed to upgrade their metal fabrication capabilities, they approached us with a clear requirements for laser cutting and welding.

His needs were specific: laser cutting for sheets (1250x2500mm) and profiles, handling thin to medium thicknesses, alongside welding black metal up to 8mm. Understanding the critical role of precision in construction, we delivered a tailored solution within 24 hours, including technical specifications and a competitive quote.

During discussions, he recognized an opportunity to streamline their workflow further and requested a press brake machine.

While their initial order for the cutting, welding, and bending machines is still in production, he approached us with an unexpected request: to help source additional smaller equipment outside our core product range.

This decision to rely on us for procurement - not just production - speaks volumes about the trust and reliability we've built.

Why Businesses in Construction Choose Us

Like the Moldovan builder who started with one machine and now relies on us for more, let SteviS help you build not just structures, but a stronger, more efficient business.

Our client, S Company, is a well-known Korean manufacturer of cast iron pipes and fittings, specializing in the production of pipeline components for various industrial applications.

With the growing production demand, the client aimed to improve cutting efficiency while maintaining clean and residue-free pipes, which are critical for their product quality.

Technical Requirements

The client first reached out to us after watching our ST-TP120 model with water-flow slag removal video online.

After careful technical discussion, our engineers found that while the ST-TP120 is an excellent choice for larger pipes, the client’s smaller pipe inner diameters (as small as φ14.28 mm) required a more compact and faster cutting solution.

For this reason, we recommended the ST-FL70F full-automatic cutting machine with copper-tube slag removal, which provides higher cutting efficiency and better adaptability for narrow pipes.

Additionally, since the client’s smallest pipe size was smaller than the standard slag-removal copper tube, our team customized thinner copper tubes specifically for their production needs.

Our Solution

After we proposed the technical plan, the client’s technical manager, overseas manager, and company president visited our factory in person to review and confirm the final configuration.

Together with our engineers, we optimized the details of the feeding system, slag removal mechanism, and cutting process parameters.The final solution consisted of three sets of ST-FL70F automatic cutting machines, each tailored to a specific pipe diameter range.

This setup ensured both high-speed performance and excellent cleanliness of the pipe interior — perfectly matching the client’s quality goals.

Inspection and Delivery

Once the machines were completed, the client come to our factory for the final on-site inspection.

They carefully reviewed the operation process including automatic loading, cutting, and slag removal for each unit.The machines passed the inspection successfully, and the client expressed full satisfaction with the performance, authorizing us to proceed with shipment immediately.

All three machines were then shipped to Incheon, South Korea, and are now ready for installation and operator training.

Customer Feedback

“These machines cut really fast — faster than we expected.

We’re very satisfied with the performance.

We’ll come back to you for our next projects.”

— Technical Manager, X Company, Korea

Client G is a well-established manufacturer specializing in stainless steel pipes and tubes, including round pipe, square tube and slotted pipes. For many years, their factory operated with traditional stainless steel tube mill production lines. However, the outdated equipment could no longer keep up with rising efficiency demands.

Two years ago, Client G planned to move into a new factory. But there was a major problem:

Client G realized that simply moving old equipment into the new plant would not solve these challenges. They needed a long-term solution.

In recent years, laser welding and cutting technology has matured and been widely adopted in stainless steel tube mills. Compared with traditional methods, laser technology offers:

Recognizing this market trend, Client G decided to explore the possibility of upgrading their production line with laser systems.

Client G visited our facilities to see how our online laser welding and cutting system works in real production lines. During the visit, we demonstrated multiple successful projects and customer cases.

These real-world examples gave Client G the confidence they needed. After careful evaluation, they decided to purchase 8 complete stainless steel tube production lines, each equipped with an advanced laser welding and cutting system.

With the new lines installed in their modern factory, Client G has achieved:

This project shows how manufacturers can stay competitive by adopting laser welding and cutting technology. Instead of moving outdated machines to a new site, Client G invested in modern production lines that deliver efficiency, quality, and long-term savings.

For stainless steel tube producers looking to modernize, Client G’s story is proof that upgrading to laser technology is the right step toward sustainable growth.

Founded in 1997, this long-established manufacturer has spent over two decades specializing in the development and production of stainless steel decorative hardware. Their core product is stainless steel door handles, but the company also produces stainless steel door locks, bathroom safety grab bars, glass door clamps, sliding glass doors, and floor spring accessories. With a strong presence across Europe and North America, they are a trusted supplier in the architectural hardware industry.

As the demand for their stainless steel door handles continued to grow, the company faced an urgent need to increase both production capacity and product quality. For years, the management team had been exploring ways to streamline operations and modernize their manufacturing processes to meet higher standards and expanding order volumes.

Upon learning that SteviS specializes in full-line manufacturing solutions for metal products, the company’s management decided to bring their product samples and visit SteviS' factory. The goal: to find a complete, efficient, and scalable production solution.

SteviS engineers conducted a comprehensive analysis of the client’s existing production workflow. Based on the assessment, SteviS proposed a fully integrated solution, including:

This complete processing line was designed to match the client’s product specifications while significantly enhancing efficiency and consistency.

With the gradual deployment of SteviS equipment, the client’s factory experienced a major transformation. Production speed increased, quality improved, and manual processes were minimized. Most importantly, the company was able to meet growing demand and win additional international orders, further cementing their leadership in the stainless steel hardware market.

SteviS – Your Partner in Smart Manufacturing

Whether you're producing hardware, furniture components, or custom metal parts, SteviS provides integrated solutions tailored to your needs. Contact us to start optimizing your production today.

Our customer is a well-established manufacturer specializing in medical rehabilitation equipment. With a 16,000㎡ production facility, they produce a wide range of products including:

Their products are widely sold in Europe, North America, Australia, and Japan, and are recognized for their reliability and ergonomic design.

In the early stages, the customer used traditional saw blade machines to cut aluminum tubes. Although they had considered upgrading to laser tube cutting technology, they were concerned about the spatter typically produced during the cutting process, which could affect the finish and safety of the parts. As a result, the project was temporarily shelved.

Everything changed when the customer learned that SteviS had launched its second-generation anti-spatter laser tube cutting machine—an industry-first solution with patented technology offering 100% spatter prevention.

Major Performance Upgrades:

Intrigued by the innovation, the customer brought their aluminum tube samples to our factory for live testing. Impressed by the clean, precise cuts and spatter-free results, they made a swift decision to purchase 5 sets of our latest model.

Today, all four machines are operating smoothly at the customer's facility. The production line has not only seen a significant increase in efficiency and product consistency, but the upgrade has also reinforced the customer's competitive edge in the global market.

SteviS is proud to support world-class manufacturers with advanced, practical, and reliable laser solutions tailored for high-precision industries like medical equipment.

A leading metal processing company based in Bulgaria has been offering laser cutting, welding, and bending services for various industrial sectors. Four years ago, the company invested in a handheld laser welding machine from a European supplier, mainly for welding steel components.

With the growing demand for aluminum parts in recent years, the customer faced a new challenge: their existing laser welder was not suitable for welding aluminum effectively.

Additionally, the machine began experiencing frequent issues, and the supplier required an annual maintenance fee of €500 just to keep it operational. The high cost of after-sales support prompted the customer to start exploring alternative solutions.

During a visit to a friend’s factory, the customer noticed a SteviS handheld laser welding machine in use. Impressed by its performance, versatility, and significantly lower price compared to European brands, the customer decided to purchase one unit from SteviS for testing.

The outcome exceeded expectations. The SteviS laser welder not only handled aluminum welding with exceptional quality, but also eliminated the need for expensive ongoing maintenance. As a result, the customer’s aluminum welding capability improved dramatically, enabling them to take on more high-precision projects with confidence.

“The difference was immediate. We were able to weld aluminum smoothly and consistently, something we struggled with before. On top of that, we’re saving on service costs every year. Choosing SteviS was absolutely the right move.”

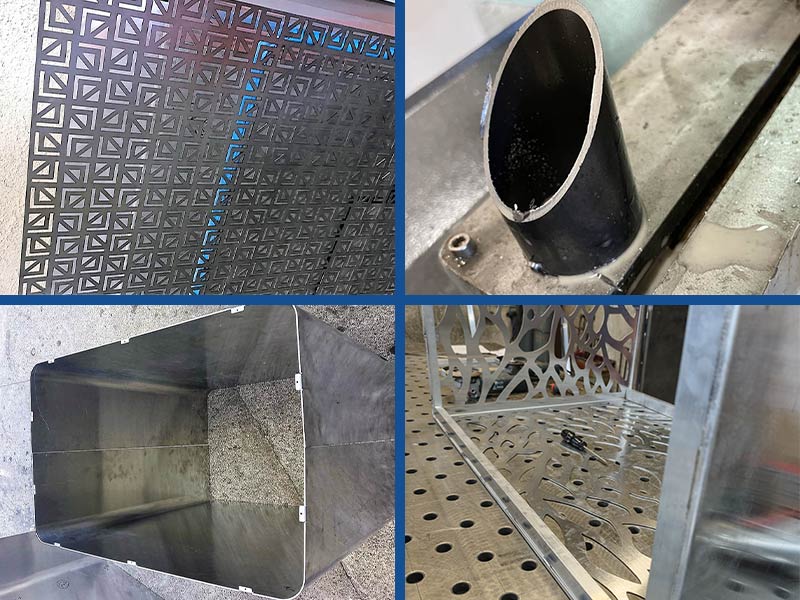

Our client, a reputable HVAC ventilation system manufacturer based in Bulgaria, initially approached SteviS with a clear goal: to enhance their production line by integrating a laser welding robot. With rising market demands and the need for higher precision in ductwork fabrication, automation was top of mind for the client.

After a thorough review of the client’s product samples and production workflow, our technical team and engineers identified an opportunity to go beyond the original request. Instead of a standard welding robot, we recommended our custom-designed automatic laser welding platform, which is better suited for the client's specific HVAC components and production volumes.

During our on-site consultation, our engineers also observed that the client's current aluminum cutting process could be significantly improved. As a result, we proposed an aluminum cutting machine that is purpose-built for the HVAC ventilation industry — delivering faster, cleaner, and more precise cuts for aluminum ducts and profiles.

Impressed by our industry-specific insights and the customized solution, the client decided to follow our recommendations. They placed an order for the specialized aluminum cutting machine to optimize their material processing line.

Once the equipment arrived at the client’s facility, our professional after-sales team in Bulgaria provided full on-site installation and commissioning support. Thanks to their rich industry experience, the setup was completed efficiently and tailored to the client’s actual production needs, ensuring a seamless transition into automated cutting and welding processes.

With the integration of SteviS’s custom automation solutions, the Bulgarian HVAC manufacturer is now equipped to produce with greater speed, accuracy, and consistency — setting a new standard in their production line.

E: info@stevistech.com

service@stevistech.com (service)