Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

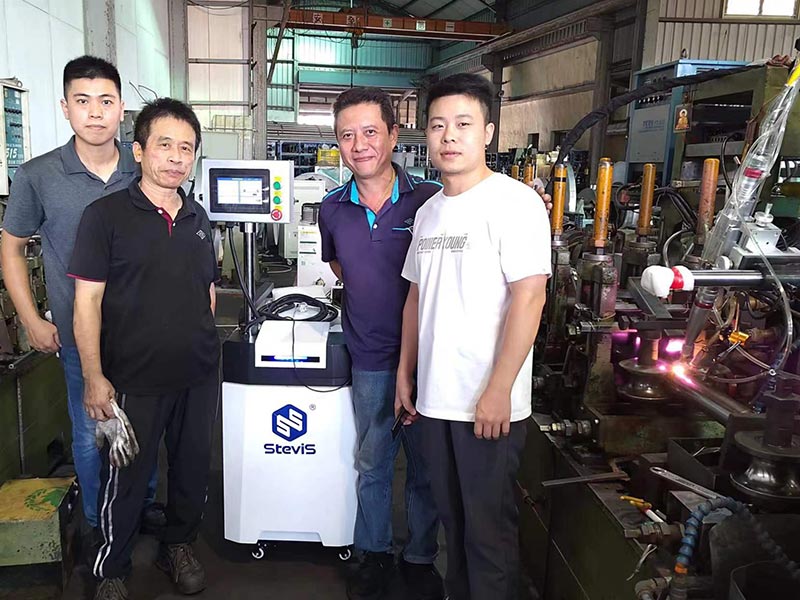

Customer: Kwang Sheng Industrial Co., Ltd.

Location: Taiwan

Industry: Stainless steel tube factory

Purchased model: SteviS ST-OLW series Laser welding machine for tube mills

Purchased time: 2024

Kwang Sheng Industrial Co., Ltd.(https://www.kstube.tw/) was established in 1973, is a stainless steel welded (TIG) tube/pipe manufacturer with 600 different kinds of tubes. It is world's most various of special shapes and size SS tubes supplier.

The customer has purchased ST-FL120F fully automatic laser tube cutting machine in 2020.

They began planning to switch to laser welding technology on the tube mills line in 2024.

They realize online laser welding will bring more stable quality, more efficient production compared with traditional TIG welding. So they reach out to find a solution with us.

And they take samples welded by this machine to perform 30% expansion test and flattening test. And they got positive test results.

According to the customer's feedback, the speed of laser welding is 3 times faster than traditional TIG welding.

We are thrilled to share a success story from one of our valued customers, a leading manufacturer of motorcycle automotive parts.

This year, they embarked on an exciting project to develop a new splash guard for the front and rear wheels, commissioned by Honda Motorcycle.

The challenge involved stamping the splash guard into shape and then requiring precise 3D laser cutting to trim the edges before the final pressing process. To achieve this, they turned to SteviS for a cutting-edge solution.

Our 3D laser cutting solution, integrated with a robotic system, delivers each cut in under one minute. This innovation not only boosts productivity but also ensures continuous cutting, significantly enhancing efficiency.

Moreover, it creates a more user-friendly working environment compared to traditional production methods.

By partnering with SteviS, our customer has achieved remarkable improvements in their manufacturing process, setting a new standard for quality and efficiency in the industry.

Customer T, located in Monterrey, Mexico, is a well-established manufacturer of motorcycle parts and frames.

Two years ago, they embarked on a project to set up an automated laser tube cutting workshop to enhance their production capabilities and efficiency.

During their search for advanced solutions, they were introduced to us through a local service provider with whom we have a strong and collaborative relationship.

This connection was crucial, as it allowed the client to gain insights into our expertise and the potential benefits of our solutions.

Intrigued by our offerings, the client engaged in detailed discussions with our team. We worked closely to understand their specific needs and operational goals. Based on these discussions, we developed a comprehensive equipment layout plan tailored to their workshop.

Additionally, we provided a customized reverse-feeding laser tube cutting machine, designed to integrate seamlessly into their production line.

The implementation process was smooth, thanks in large part to the support and coordination of the local service provider. They played a key role in facilitating communication and ensuring that the installation and setup met the client's expectations.

As a result, the client successfully deployed the equipment and commenced production. The new automated workshop has significantly improved their manufacturing efficiency and positioned them for future growth in the competitive motorcycle parts industry.

Our High-Speed Small Tube Laser Cutting Machine ST-FL40 has been highly praised once again.

Our customer from Slovenia has chosen us and placed an early order. Their requirements are that tubes are mostly pharmacy and medicine, it is important that the cuts are accurate, nice and clean and they want to use use machine for production nozzles, smaller washing inserts, pipeline.

On-Site Experience, Trust Built on Professionalism

To help our customer better understand our equipment, we arranged for them to visit our site in Italy to see the machine in action. The customer witnessed firsthand the outstanding speed and precision of the ST-FL40 and expressed great admiration for our technical team.

Professional Service, Full Support

From the initial communication to the on-site demonstration, our team provided professional technical support and detailed explanations, ensuring the customer understood every aspect of the equipment. Our service not only resolved their concerns but also filled them with confidence for future cooperation.

Early Order, A Choice of Trust

After an in-depth understanding and experience, the customer was impressed by our machine's performance and our professional service, leading them to place an early order for the ST-FL40. This decision showcases their high trust in our products and services.

Customer S is a family business in Australia, specialized in the production of air conditioning grilles and related accessories.

The reason they considered laser tube cutting machine is mainly to improve the current production situation of high labor cost, low efficiency, and poor precision. In view of this, according to their needs, we provided them with a cutting solution that is fast, efficient, highly precise, and cost-effective.

Customer Information

| Industry | Air conditioning grille field |

| Outer diameter | φ10 mm |

| Wall Thickness | 1.6 mm |

| Cutting length | 8 - 30 mm |

| Material | Aluminum alloy |

| Tolerance | ±0.05 mm |

| Selected machine | ST-FL40F |

Machine test videos:

Why did they choose us in the end?

"Among the responses from many suppliers, your reply is the most comprehensive. During the communication process, you can provide more detailed information, such as sales situations in other parts of the world, such as the United States, Slovenia, etc. We can feel that your machine is reliable and of high quality. Another important point is that before I decided to buy the machine, you took the initiative to conduct sample testing for us and provided more machine videos. This kind of service is very satisfactory to me." - Customer S

Provide Training on site

SteviS solves your production problems and provides efficient metal processing solutions. Let us make progress together and achieve mutual benefit and win-win results!

| Main product | Automobile bumper |

| Material | High strength steel |

| Requirement | The speed of tube mill should be reached 5 meters/min |

| Fiber laser power | 12000W |

| Outer diameter | 50*50 mm |

| Wall thickness | 2.5 mm |

| Main product | Frame of Villa's gate |

| Material | Galvanized steel |

| Requirement | Firmly and thoroughly welding, no sand holes, no spatter |

| Fiber laser power | 6000W |

| Wall thickness | 1.2 mm |

| Speed of the tube mill | 14 meters/min |

| Main product | Natural gas pipeline |

| Material | Stainless steel |

| Requirement | The wall thickness of welded seam after grinding shall not be less than 8% |

| Fiber laser power | 6000W |

| Wall thickness | 1.5 mm |

| Speed of the tube mill | 3.3 meters/min |

| Main product | Battery Tray |

| Material | High strength steel |

| Requirement | The welded seam is flat and the width is uniform. No defects including cracks, leaks, false welds, spatter, pores, undercuts, burn-through, or unwelded are allowed. |

| Fiber laser power | 6000W |

| Wall thickness | 1.5 mm |

| Speed of tube mill | 5 meters/min |

| Main product | Submarine communications cable tubes |

| Material | Stainless steel 2205 |

| Requirement | Continuous welding of 10,000 meters without interruption, Can pass the ductility test after annealing, High temperature and corrosion resistance |

| Fiber laser power | 6000W |

| Outer diameter | 6.35 mm |

| Wall thickness | 1.5 mm |

| Speed of tube mill | 4 meters/min |

E: info@stevistech.com

service@stevistech.com (service)