Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

In October 2024, a leading stainless steel bathroom accessories supplier in Europe discovered SteviS Tech at the MACHTECH 2024 in Bulgaria. The customer specializes in providing complete stainless steel bathroom solutions across Europe and was actively seeking advanced equipment to upgrade their production line.

The customer required a full set of equipment for manufacturing various stainless steel bathroom accessories. This included machines for pipe laser cutting, pipe fittings laser cutting, welding, and polishing. The goal was to streamline their in-house production and enhance efficiency and product quality.

Shortly after the exhibition, SteviS organized an on-site factory visit with both our sales and engineering teams. During the visit, we:

To validate our solution, the customer provided product samples for laser welding tests. The tests were conducted using SteviS’s advanced welding technology, specifically designed for thin stainless steel components. The customer was impressed with the high precision and clean welds, which passed their internal quality inspections.

After successful testing and technical discussions, the customer confirmed their decision to adopt SteviS’s complete stainless steel bathroom production line. This included machines for:

By partnering with SteviS, the Bulgarian customer now benefits from an integrated production line that improves efficiency, ensures consistent product quality, and supports future growth. This project highlights SteviS’s ability to deliver end-to-end manufacturing solutions tailored to the stainless steel bathroom industry.

The Challenge: Scaling Quality in Aluminum Welding

Since 2017, O Company has excelled in crafting premium wood-aluminum windows, doors, and facades. But as demand surged—from 200㎡ to 3000㎡ monthly—their welding process became a bottleneck. Traditional methods struggled with aluminum’s complexities: inconsistent welds, slow speeds, and rework. They needed a solution to boost capacity without sacrificing precision.

The Solution: SteviS 2KW Handheld Laser Welding Machine

Drawing on our decade of expertise in European industrial laser systems, SteviS recommended the 2KW Full-Power Handheld Laser Welder—engineered specifically for aluminum excellence.

Why SteviS Stood Out:

✅ Aluminum-Optimized Performance: Integrated with a specialized aluminum wire feeding system for flawless, spatter-free welds.

✅ Industrial 2KW Power: Penetrates thick profiles swiftly while maintaining aesthetic seams—no grinding needed.

✅ Handheld Flexibility: Weld intricate corners and curves on window frames effortlessly, slashing repositioning time.

✅ Zero Learning Curve: Intuitive operation allowed O Company’s team to master it in days.

The Transformation: From 3000㎡ to 5000㎡—and Beyond!

Within weeks of deploying SteviS, O Company revolutionized their workflow:

66%+ Production Surge: On track for 5000㎡ monthly—a goal once deemed unreachable.

Flawless Finish: Laser precision eliminated post-weld cleanup, cutting labor costs by 30%.

Versatility Unleashed: From slim mullions to heavy-duty sashes, every joint met structural and cosmetic standards.

"SteviS didn’t just speed up welding—it redefined our quality ceiling. The aluminum wire feeder was a game-changer!"

— O Company Production Lead

When engineer K from a leading Russian scaffolding manufacturer reached out in March 2024, our team SteviS recognized an opportunity to turn technical precision into lasting partnership.

We delivered value below:

1. Precision Meets Speed

Upon receiving engineer K detailed specifications for laser pipe cutters (including chuck sizes, auto-loading features, and power requirements), we responded within 24 hours with customized proposals, test videos, and material samples. Our agility in addressing technical queries—from cutting speeds to bed construction—built immediate trust.

2. Beyond Sales: Building Confidence

Understanding the client’s engineer-driven decision process, we:

(1)Facilitated factory visits with a local satisfied customer, to showcase machines in action.

(2)Created a dedicated WhatsApp group for real-time collaboration between their team and our technical experts.

(3)Provided transparent comparisons against competitors, focusing on durability, after-sales support, and cost efficiency.

High-Efficiency Laser Tube Cutting Solution for Folding Beds and Beach Chairs

Customer F, a leading furniture manufacturer in Russia, specializing in folding beds, beach chairs, and outdoor furniture, was facing growing production demands and needed a reliable tube cutting machine that could deliver both performance and efficiency.

In a conversation with a friend, the customer was introduced to SteviS Tech, a professional manufacturer of laser tube cutting machines and metal processing equipment. Intrigued by SteviS's reputation, the customer visited our official website and reviewed multiple customer case studies showcasing successful projects worldwide.

To ensure the machine would meet their specific production needs, the customer requested a sample cutting test. Our engineering team quickly arranged the testing, and the customer was able to evaluate the machine’s performance via detailed cutting videos.

The high-speed cutting, smooth edge quality, and stable operation fully met the customer’s expectations.

In June 2024, the customer confidently placed the order.

After the equipment arrived at the Russian factory, SteviS’s local after-sales service team in Russia provided on-site installation, commissioning, and training, ensuring smooth and efficient startup.

Today, the machine is running smoothly, helping the customer significantly increase production capacity, reduce manual cutting errors, and improve product consistency.

At SteviS Tech, we are committed to delivering turnkey laser cutting solutions with professional service support to customers worldwide.

For over 30 years, N Company (a California-based pioneer in advanced metal manufacturing) has set the industry standard in precision services—from CNC machining to complex die fabrication. But when production bottlenecks threatened their wheel center division, they turned to SteviS for a breakthrough.

The Challenge:

As demand surged, N Company’s reliance on manual welding slowed throughput. Consistency wavered, labor costs climbed, and MIG welding’s radiation risks lingered. They needed a future-proof solution-fast.

The SteviS Advantage:

Leveraging N Company’s 3D design data, SteviS engineered a turnkey welding ecosystem:

Fully automated system built exclusively for N Company’s wheel specs.

Quad welding heads enable 400% faster cycle times vs. manual processes.

Flawless consistency for high-volume runs.

Seamless integration for auxiliary components.

↓ 70% labor dependency with ↑ 50% throughput.

Precision welding 24/7 with zero fatigue.

Agile solution for prototypes, repairs, and low-volume orders.

3x faster than traditional MIG welding.

Radiation-free operation—eliminating PPE requirements and health hazards.

Results That Speak Louder Than Sparks:

“SteviS didn’t just meet specs - they redefined our production ceiling,” lauds N Company’s leadership.

“Their robust machinery, intuitive controls, and relentless quality under heavy volumes make them indispensable partners. We’ve slashed costs, skyrocketed output, and safeguarded our team—all without a single compromise.”

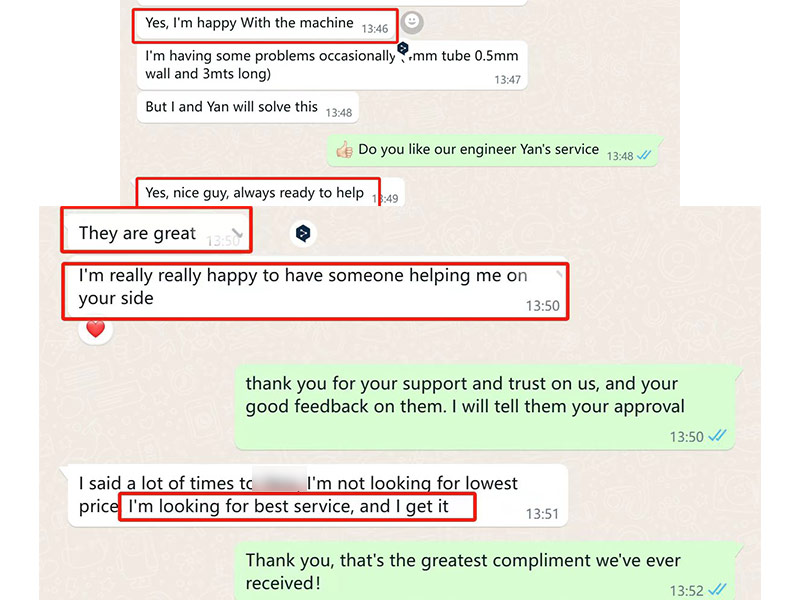

Client F, based in Portugal, specializes in developing security protection technologies for ATM equipment and supplies precision tubular components for ATM manufacturing. As part of their production process, they handle stainless steel and aluminum tubes with a diameter of 4mm. Each part requires drilling up to 100 tiny holes with a diameter of only 0.5mm — an extremely demanding task for any processing equipment.

Previously, the client relied on CNC equipment for tube processing. However, the CNC process proved to be slow and inefficient for such high-density, small-diameter hole drilling. As production demand increased, the client urgently needed a faster and more precise solution that could ensure both speed and high accuracy in micro-tube processing.

While searching for new equipment, the client came across our Small diameter tube precision laser cutting machine on Alibaba. The advanced design and specialized capabilities of this machine immediately caught their attention. After an initial consultation with our engineers, we recommended performing a sample cutting test to demonstrate the machine’s precision and performance.

Our engineering team conducted the sample test and shipped the finished samples to the client for evaluation. Upon receiving the samples, the client was highly satisfied with both the cutting quality and processing efficiency. The machine's ability to cut 0.5mm holes with high precision and speed fully met their technical requirements.

Impressed by the performance, the client made the purchasing decision within just one month after receiving the samples. The machine was delivered and successfully installed at the client’s facility in early February this year. Under the remote guidance of our experienced engineers, the client’s team quickly became familiar with the machine's operation and production processes.

Shortly after putting the machine into production, the client provided us with positive feedback, highlighting the significant improvements in both processing speed and product consistency. Based on their successful experience, the client is now planning to expand their production capacity. Prior to the client’s next equipment purchase, we also proposed an upgraded machine solution to further optimize their production line.

One of Kuwait's leading engineering company A has boldly stepped into advanced laser welding technology to tackle the challenges of heavy structural fabrication.

Specializing in large-scale construction projects that require welding substantial and thick materials, the company purchased two high-power 3kW handheld laser welding machines from us in March 2025.

As infrastructure projects continue to grow in scale and complexity, having reliable, high-performance welding equipment has become increasingly crucial.

These industrial-grade laser welders provide them with unprecedented flexibility to handle complex welding tasks at construction sites and fabrication workshops.

Unlike traditional methods that struggle with thick materials, our laser welding solutions achieve deep penetration while minimizing heat distortion—making them ideal for structural steel, thick plates, and other demanding applications.

Our client, a leading stainless steel corrugated pipe manufacturer in Turkey, approached SteviS Tech via LinkedIn after watching our video demonstration of the latest laser welding machine for stainless steel pipe production lines. Recognizing the significant advantages of laser technology over traditional welding processes, they sought to upgrade their production capabilities to meet growing market demand and enhance product quality.

By adopting SteviS Tech’s laser welding machine for stainless steel corrugated pipe production and our handheld laser welding machine for secondary operations, the Turkish manufacturer has upgraded its entire welding workflow. The combined solution delivered substantial gains in production efficiency, reduced costs, and improved end-product quality—positioning them to capture new market share both domestically and internationally.

If you are a stainless steel pipe manufacturer or an industrial fabricator looking to boost production efficiency and eliminate traditional welding bottlenecks, contact SteviS Tech today to learn how our laser welding solutions can transform your operations

One of Georgian renowned outdoor furniture manufacturer had long struggled with welder shortages and inconsistent welding quality, which directly impacted production efficiency and market competitiveness.

In August 2024, the company purchased our industrial 6-axis welding robot, which not only significantly improved welding quality but also reduced production cycles.

During their visit to our factory in December of the same year, they were so impressed that they placed an additional order for a 1.5kW handheld laser welding machine to further enhance flexible production capabilities.

Today, the client has achieved higher welding pass rates, shorter order fulfillment cycles, and sustainable profit growth through automated production—effectively resolving their core challenges and delivering a true win-win in both quality and efficiency.

Our customer is a Belgian entrepreneur who operates a large-scale furniture manufacturing facility in Indonesia. The factory specializes in producing custom metal furniture components for both local and international markets.

Before contacting us, the client was already using a combined plate and tube laser cutting machine and a separate tube cutting machine from other suppliers. However, both machines fell short of expectations:

With production demands increasing, the client was looking for a professional, high-performance laser cutting solution that would meet their needs for both tube and plate processing.

After just two days of efficient communication and technical consultation, our team delivered a tailored solution that won the client’s trust:

Unlike many brands that rely on assembly only, we manage every step of the production process in-house — from frame machining to using our own laser cutting machines to fabricate machine parts. This commitment to quality and control left a strong impression on the client.

The client was thoroughly impressed with our professional approach, rapid response, and solid technical advantages. Within two days of initial contact, they confirmed their order without hesitation.

The new equipment is now fully integrated into the client’s production line, delivering superior performance and efficiency. The customer has also expressed strong interest in expanding cooperation with robotic welding solutions for the next phase of automation.

This collaboration is not just a successful transaction — it marks the beginning of a long-term partnership. With our reliable machines and dedicated service, we're excited to continue supporting the customer’s vision for a smarter, more efficient factory.

E: info@stevistech.com

service@stevistech.com (service)