Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

| Main product | Container beam (Micro Tube) |

| Material | Steel |

| Requirement | Weld through, weld firmly, can be bent in reverse, can be withstand pressure of 1080 MPa |

| Fiber laser power | 12000W |

| Wall thickness | 1.3 mm |

| Speed of tube mill | 13 meters/min |

| Main product | House load-bearing beam profile |

| Material | Galvanized steel |

| Requirement | No pores, convex outside and flat inside, beautiful welds |

| Fiber laser power | 6000W |

| Wall thickness | 3 mm |

| The speed of tube mill | 2.6 meters/min |

| Main product | Automotive exhaust tubing |

| Material | Stainless steel 409 |

| Requirement | Can be bent and flared |

| Fiber laser power | 3000W |

| Wall thickness | 1.5 mm |

| The speed of tube mill | 2.6 meters / min |

Customer A, based in Bulgaria, specializes in the production of aluminum alloy ladders. They were initially seeking a welding robot solution to enhance their production efficiency.

After a factory visit, the customer was recognizing our expertise as a provider of professional welding robot workstation solutions. They decided to send samples for welding tests.

Upon receiving the samples, we discovered that the weld seams were excessively large, making welding unfeasible.

Further investigation revealed that the client's current manufacturing process involved manual cutting and welding, resulting in significant workpiece inaccuracies.

To address the issue, we recommended that the customer first improve the quality of their workpieces by using an automatic aluminum pipe and profile circular saw cutting machine.

The customer adopted the new aluminum pipe circular saw cutting machine, which significantly improved their product quality.

They sent us new samples for further testing again.

Considering the large size of the products they manufacture, we designed a welding robot workstation solution featuring ground rails and 2 sets of positioners to accommodate their needs.

Once the equipment was completed, the customer come to our factory for acceptance testing and received comprehensive training from our engineers.

The equipment was then shipped to the client's facility in Bulgaria, where it was quickly put into operation.

Customer Case

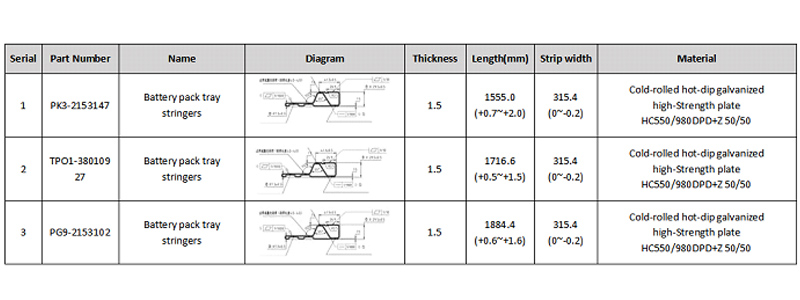

Project name: BYD

Material: High-strength steel

Main product details

Note: the welding speed need to meet 5 m/min

Technical requirements

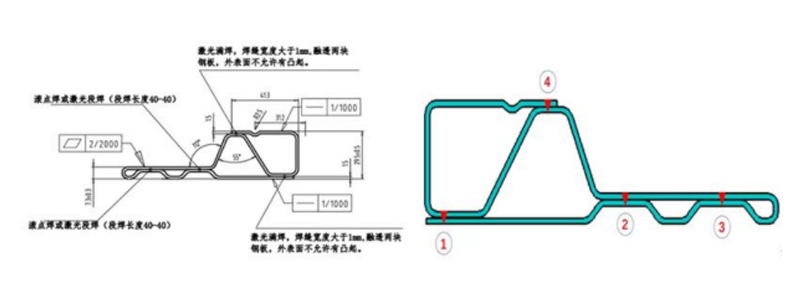

1. Welding seam position: The product adopts 4-pass laser welding, the specific position is shown in the figure below:

2. Appearance requirements

* Overall appearance requirements: No corrosion, rust, metal debris, oil stains, water marks & water stains as a whole. No water or oil is allowed to be stored in the steel cavity;

* Rolling beam assembly surface: The surface is smooth and clean, without defects such as pits, convex bumps, welding slag, bump marks, distortions, etc.; the welding joint has a smooth transition;

*The burrs cut off at the end are ≤0.3mm, and the hands will not be cut if touched by hand;

*The weld surface should be smooth and uniform in width. Defects such as cracks, missing welds, false welds, spatter, pores, undercuts, burn-throughs, and unwelded joints are not allowed. The weld protrusion on the non-assembly surface should be ≤0.3.

3. Welding seam technical requirements

* 0.5mm≤weld width≤1.5mm

* The penetration depth of the second plate during stack welding ≥ 0.5mm

* Welding strength≥ 90% of the base metal.

Professional solutions

Solution: ST-OLW Online Laser Welding Machine

Power: 12000W

Result: After rigorous testing and acceptance, the customer purchased 6 sets of ST-OLW series online laser welding machines at one time. After using online laser welding, we helped customers solve the problem of producing new products that could not be produced by traditional high-frequency welding methods.

Introduction to online laser welding technology

Online laser welding is an efficient and precise welding method that uses a high-energy laser beam to directly act on the surface of the material, causing the material to melt and solidify rapidly to form a strong weld.

Whether it is a traditional oil vehicle or a new energy vehicle, in the current environment of cost reduction, efficiency improvement and efficient production, metal profiles such as automobile exhaust pipes and battery trays are widely used in one-piece online laser welding.

Laser, as a new type of non-contact welding method, has greatly improved production efficiency and process intensity.

Advantages of online laser welding technology

1. High efficiency: The speed of laser welding far exceeds that of traditional welding methods, greatly improving the work efficiency of the production line.

2. High quality: Laser welding can achieve precise control, high weld quality, and greatly reduce subsequent repair work.

3. Low thermal impact: The heat affected area of laser welding is small, which reduces the thermal deformation of the material and ensures the dimensional accuracy of the product.

4. Strong material adaptability: Laser welding is suitable for a variety of materials, including carbon steel, stainless steel, aluminum alloy, etc., to meet the needs of different pipe materials.

5. Environmentally friendly: Compared with traditional welding, laser welding produces less exhaust gas and noise, and is more environmentally friendly.

As the automotive industry continues to improve its requirements for product quality and production efficiency, online laser welding technology, with its unique advantages, has become the preferred technology for upgrading and transforming automotive pipeline production lines.

As a pioneer in online laser welding technology, our company has rich industry experience and technical accumulation, and is committed to providing efficient and high-quality welding solutions for automotive pipeline production.

Choose us and let us open a new chapter in automotive pipeline production together and achieve a double leap in production efficiency and product quality.

Related products

Customer R is a renowned player in the furniture industry in Bulgaria, understood the importance of staying at the forefront of technological advancements to meet the evolving demands of the market.

Their dedication to craftsmanship and precision led them to explore advanced solutions that would not only optimize their production processes but also elevate the aesthetics and functionality of their furniture designs.

After careful consideration and consultation, the client made a strategic decision to acquire ST-TP120 high-speed automatic laser tube cutting machines and ST-PL3015 sheet metal laser cutting machine.

Machine Test video:

SteviS professional fiber laser cutting machines are marked a significant leap for our client, enabling them to achieve unparalleled efficiency and accuracy in cutting and shaping tubes for their furniture components.

These machines revolutionized their production line, allowing for swift and precise fabrication of intricate designs with remarkable speed.

We hope we can open up the Bulgarian market together and work together for a win-win situation.

Related products

Customer K is a tubular furniture manufacturing company situated in Plovdiv, Bulgaria, including school furniture and file cabinets.

The customer visited one of school furniture factory in Bulgaria in 2023 and found that they are used ST-FL80F series fast metal tube laser cutting machine.

The customer was deeply impressed by the ultra-fast cutting speed displayed by the equipment, which also made the customer remember our company.

The customer found that there are two different laser tube cutting machines ST-FL80F & ST-TP120F in our company's official website. But the customer need us to explatin the difference between these two machines.

He also share his requirements to us:

| Round tubes diameter | 10-80 mm |

| Square profile diameter | 10*10-50*50 mm |

| Rectangular profile diameter | 20*10-60*40 mm |

| Oval tubes diameter | 26*12 mm |

| Cutting thickness | Maximum 2.5 mm |

| Cutting length | Maximum 4,200 mm |

| Material | Cold rolled welded tubes from carbon steel / stainless steel |

| Raw material length | 6,200 mm |

Based on the customer's production capacity and the size of the pipes processed, we recommended the ST-TP120F to the customer and explained to the customer the difference between ST-TP120F laser pipe cutting machine and the ST-FL80F machine.

In addition, we also answered more details about the ST-TP120F series laser pipe cutting machine to the customer:

Q:what's the gas consumption?

A:Machines are suitable for both compressor air and nitrogen, they can also use oxygen by adding the proportional valve.

*compressor air: about 0.2-0.3m³/hour. Suitable for all metal cutting, low cost, only power consumption 8kW/hour. More than 95% of our customers choose compressor air for lower production cost.

*oxygen: 0.3-0.5m³/hour, suitable for carbon steel with better cutting result & less inner burr for thick pipes.

*nitrogen: 0.5-1m³/hour, suitable for stainless steel for better cutting result, more shinny on the surface.

Suggestion on compressor: must be high pressure(≥16 bars) , clean & dry. (We will recommend in quotation)

Q: how do I collect long pipes?

A: We can offer long workpiece supports when you cutting over 1500 mm.

Q: Is there any additional function to detect the tube seam?

A: Yes, we can add the seam detection function.

1) Photoelectric sensor - uses the difference in reflection thresholds on the surface of the pipe irradiated by laser to realize weld seam identification. It is required that the color difference between the weld position of the pipe and the surface of the pipe is relatively large.

2) AI image recognition sensor - realizes weld seam recognition by comparing weld seam position images on the pipe surface or inner wall

Q:Is there a way to connect the machine with the internet, so that you can access it from a distance and do if anything is needed such as reprogramming, debugging, finding an error or etc.

A: We offer a Wireless network card with each machine, with it machine can connect with the internet and our engineer offer technical support remotely.

The customer was very satisfied after receiving our answer. At the same time, our company was conducting a promotion event at the end of 2023, which can offer free after-sales service.

So the customer decided to purchase our equipment quickly.

Machine test videos:

Machines in customer factory:

2024

2025

Customer feedback

Related products

Customer D is located in Bulgaria and mainly produces various furniture and related accessories, single-layer and double-layer bed frames. The finished products are mainly supplied to IKEA.

In order to cope with multiple designs of IKEA's furniture products, Customer D has been considering using new processing style for production from 2020, because the equipment in their factory at that time could no longer meet production needs.

Within 2 years, the customer has purchased 5 sets of automatic metal pipe and profile laser cutting machines.

When the customer discovered that the productivity, efficiency and product qualification rate of laser cutting had increased, they considered using automation in the welding module.

The customer specially sent some bunk bed frame samples to us for testing.

Although the customer hopes that all production equipment will be converted to laser processing, we consider that the bunk bed frame structure must be strong because it is used for children. Therefore, the laser welding is not enough strong for bunk bed frames processing.

Machine testing before shipment:

Machine in customer factory:

So far, customers have purchased 7 sets of automatic laser pipe cutting machines, 12 sets of welding robots, and 2 sets automatic laser welding machines from us.

In April 2024, the customer has ordered 13 sets of machines to us, including sheet metal laser cutting machine, metal pipe and profile laser cutting machine and laser welding robots. We have finished production now and prepare for shipment.

We believe that our customers will go further and further on the road to factory automation and can also serve as a benchmark for local manufacturers.

Customer Feedback

P.S.:

You can know more details about our European customer cases through these links:

Italian micro-tube products factory

School furniture manufacturer in Bulgaria

Stainless steel railings manufacturer in Slovakia

Leisure furniture manufacturer in Russia

Tubular furniture manufacturer in Bulgaria

Related products

Customer M is a well-known publicly listed company based in WI, United States, specializing in the research and manufacturing of automotive and household air conditioning tubes.

Established in the early 20th century, with subsidiaries and factories in Germany, Italy, Mexico, Brazil, India, and China now.

Before using laser machines, their factories previously used CNC circular saw pipe cutting machines to process copper tubes used in the air conditioning industry.

However, the function of circular saw cutting machines were limited to only cutting off, requiring additional punching processes.

The complicated processing procedures force customers to consider using a more efficient processing method - laser cutting.

What's more troublesome is, due to the small diameter of the tubes they processed, The customer found a lack of manufacturers in the United States market producing equipment suitable for processing such precision tubes.

The customer sought a suitable supplier outside United States and discovered our high-speed precision tube laser cutting machine through our company's function.

Intrigued by our machine, they reached out to us with an inquiry.

The customer made the following requests to us:

| Material | Copper |

| Cutting diameter | Outer diameter 7.95-22 mm round tube |

| Cutting thickness | 0.5-2 mm |

| Accuracy | ±0.05 mm |

| Other requirement | Machine should be met USA standards |

Understanding the customer's need to cut copper tubes, we equipped the machine with fiber laser source that excelled in cutting anti-reflective materials (Including aluminum, brass and copper).

Upon completion of machine production, we conducted tests using samples of tubes provided by the customer.

Machine test videos:

Once the equipment arrived at the customer's site, we provided online installation guidance services to ensure a smooth setup process. Although it was the first time for the customer to come into contact with laser cutting equipment, through the efforts of our after-sales team, the customer successfully used the machine.

Machine in customer factory:

Related products

E: info@stevistech.com

service@stevistech.com (service)