Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

One of our key customers in Mexico, a stainless-steel tube manufacturer, originally purchased SteviS laser tube cutting machines through a local distributor. Since installation, the machines have been running smoothly and consistently, delivering stable performance every day.

The introduction of laser tube cutting significantly improved both the cutting output and the overall quality of their products. However, the downstream processes—such as welding and polishing—were still handled manually using traditional TIG welding. As cutting speed increased, these manual steps became a bottleneck. Large volumes of semi-finished products started piling up, creating delays and reducing overall production efficiency.

Although the customer’s city has no shortage of highly skilled welders, maintaining a long-term team of experienced welders became an increasingly heavy financial burden. The imbalance between fast, automated cutting and slow, manual post-processing pushed the company to seek a solution that would increase capacity without significantly raising labor costs.

To solve this challenge, the customer decided to introduce new technology—robotic laser welding. Before confirming the purchase, they sent us samples for welding trials. We performed full welding tests and quality inspections, and as always, the customer was very satisfied with the results.

Once the machine arrived in Mexico, our SteviS after-sales engineer traveled to the customer’s factory to provide on-site installation, calibration, and operator training. With the engineer’s guidance, the customer’s technical staff quickly mastered the system and began running production confidently.

This upgrade has already helped the customer greatly increase productivity and stabilize product quality. In the next phase, SteviS will provide a customized polishing solution, helping the customer further automate their production line and achieve even higher efficiency.

We recently worked with a practical business owner from the Netherlands who runs a door and window fabrication shop. Like many manufacturers, he faced two key challenges: finding skilled welders was difficult, and meeting strict European safety standards was a must.

He found one of our 2KW platform laser welding videos on our YouTube Channel and saw a potential solution. What happened next was straightforward and efficient.

He contacted us and confirm order, just within 1 week!

Here’s how it worked:

The entire process was built on clear communication.

When he asked about the custom enclosure, our engineering team provided a design within a short timeframe. There was no sales fluff - just practical answers to practical questions.

If your business faces similar challenges with skilled labor or safety standards, let's talk. We specialize in providing reliable, customized welding solutions that just work.Reach out today to see how we can help solve your specific production needs.

Tired of inconsistent welds, rising labor costs, and the constant hunt for skilled welders? You know the drill – the sparks, the heat, the bottlenecks. What if you could achieve perfect seams, every single time, while boosting productivity and safety?

That's exactly what customers in Bosnia and Herzegovina envisioned. As a leading provider of metal processing equipment, serving both large-scale and medium production, they knew their manual welding processes were holding them back. Seeking a smarter solution, they found us from our official website.

They are not just looking for a robot; they need a strategic partner. Through detailed discussions, multi meetings, we deep into their specific challenges, production lines, and goals. We didn't offer a one-size-fits-all solution; we crafted a winning strategy.

Finally we offer them one set industrial Robot and one Cobot.

Industrial Robot:Taking over high-volume, repetitive welding tasks with unmatched speed and unwavering consistency.

Cobot:Working safely alongside human operators for intricate welds or smaller batches, enhancing flexibility.

For our customer, this meant:

A Safer Shop Floor: Removing operators from hazardous welding fumes and sparks.

Future-Proofing:Gaining the agility to adapt to changing demands.Whether you're tackling massive production runs or intricate custom pieces, we have the robotic expertise and collaborative approach to transform your welding operations. We listen, we strategize, and we deliver solutions that work seamlessly for your unique factory floor.

At first we received the inquiry and drawings from scaffolding manufacturer from Serbia. Their challenge? To automate complex welding tasks for enhanced productivity and quality.

We quickly analyzed the drawings, and leveraging our deep industry experience, presented not one, but several tailored solutions. We offered options both with and without positioners, clearly outlining the benefits of each.

Through productive discussions, we fine-tuned the perfect system for their specific needs: a powerful 2-meter welding robot paired with two custom-built, extra-long 3-meter positioners. This setup meet their welding requirments, dramatically boosting their output.

The story got even better. In early October, the client traveled to the Bulgaria Expo. He didn't come alone; he brought his business partner to meet us in person. Impressed by our technical expertise and the clear value of the proposed solution, they made a decisive move.

The result? An initial discussion about one system turned into a signed contract for four welding robots.This story isn't just about selling machines. It's about understanding, partnership, and delivering real-world results. We provide more than just equipment; we provide smart, efficient automation solutions that help our clients grow and compete.

In an Italian factory specializing in the production of fences and handrails, the client faced challenges common to many manufacturing enterprises: a wide variety of product sizes, low welding efficiency for large workpieces, and limited factory space—with only 8.8 meters x 5.5 meters available for new equipment layout. How could they meet the welding demands of large workpieces while remaining flexible enough to adapt to high-mix, low-volume production characteristics within such a constrained area?

After an in-depth analysis of their needs, instead of offering a standard solution, we formed a dedicated technical team to develop a highly integrated, tailor-made automated welding system for the client:

Innovation Highlight: Adjustable Fixtures—Unlocking Flexible Production

Addressing the core challenge of the client’s diverse workpiece types, standard fixtures would have fallen short. Our technical team quickly responded to the client’s workpiece specifications by designing an innovative adjustable fixture system.

These fixtures feature multi-position adjustability, allowing secure clamping of fence and handrail workpieces of various sizes and shapes through simple mechanical adjustments. This enables a single fixture set to handle multiple product types, saving the client significant investment in specialized tooling and reducing changeover time—maximizing the system’s flexibility and value.

The result is a compact yet highly efficient working cell that turns limited space into limitless potential.We understand that every client’s production environment is unique. We provide not just advanced robotic equipment, but also deep process insight, efficient technical collaboration, and customized end-to-end solutions. From spatial planning and equipment selection to the design of core tooling, we are committed to being your trusted automation partner, working together to overcome production challenges and create greater value.

We recently delivered a 6kW laser cutting machine to a client in Italy. This collaboration serves as a potential reference for your own equipment selection process.

Project Background: Power Selection Driven by Practical Needs

During the initial project phase, the client carefully weighed the options between 3kW and 6kW models. To assist the client in making the most informed decision, we did not simply recommend the higher-power model. Instead, we invited the client to provide samples of their typically processed materials, thicknesses, and graphics for live cutting tests at our technical center.

The tests focused on comparing the following aspects between the two power levels:

Based on the actual test data, the client clearly recognized the long-term productivity gains and better processing quality offered by the 6kW machine, confirming their choice.

The Solution: Balancing Space, Safety, and Automation

After determining the power, the client's other key concern involved their actual workshop conditions: limited space and high safety requirements.

Together, we settled on a horizontal-structure cutting machine with a fully enclosed protective housing. This choice was based on the following considerations:

Conclusion

This machine accurately addresses the client's specific needs regarding power, space, safety, and automation. We believe that the right equipment is a tool that integrates seamlessly into the production process and effectively solves problems.We are committed to providing reliable, verifiable solutions through professional preliminary communication and real-world cutting tests.

n material processing, the capabilities of standard equipment have limitations. A customer needed to precisely cut large acrylic tubes with dimensions (3000mm in length, maximum diameter 300mm), exceeding the processing range of standard laser cutting machines. General-purpose laser cutting solutions often fall short. We focus on solving these special cutting needs through customized engineering.

Customer Needs and Challenges:

The core challenge lies in achieving stable support throughout the entire stroke, ensuring rotational accuracy of the large-diameter tube, and obtaining a smooth, stress-free cut surface.

Solution:

We designed a dedicated CO2 laser cutting system for the customer. Key customization points include:

This customized system enables customers to:

We possess full-process technical capabilities, from requirements analysis and mechanical design to system integration and process debugging. For non-standard processing needs, we focus on providing practical solutions through technical evaluation and engineering implementation.If you have special requirements regarding materials, dimensions, or processes, please feel free to contact us. We are happy to explore the feasibility of implementation from a technical perspective and provide targeted equipment solutions.

Is "handcrafted quality" at odds with "mass production"? For one of Bulgaria's most renowned furniture brands, this was a daily struggle. Their designs were beautiful, but their welding process? Stuck in the past. Skilled welders were hard to find, and consistency was a constant challenge. They dreamed of scaling their art without sacrificing the perfection they were famous for.

That’s where our story begins. In May of this year, we visited their factory. We didn’t just sell; we listened. We walked the production floor, saw the bottlenecks, and understood their vision for growth. They needed a solution that was precise, reliable, and could handle the intricate frames of their premium furniture.

We equip with 2 sets of Welding Robot: 2m Robot Arm+ 2 set of positioners.

We use machines, will reach below:

Our client didn’t just get machines; they got a key to future growth.Choose SteviS, let you feel sense of security!

In early 2025, a furniture manufacturer based in Istanbul, Turkey began evaluating automation options to improve production efficiency. Before making a decision, the customer wanted to fully understand the investment involved in robotic welding equipment and compare it with the rising cost of hiring skilled welders.

During his search for reliable suppliers, he spoke with a Georgian friend - who also happens to be our long-time customer. Through this connection, he learned that we have extensive experience providing robotic solutions specifically tailored for the furniture industry. This prompted him to reach out to us for deeper discussions.

As we began talking, we discovered an important detail: three years ago, the customer had purchased our ST-TP220 laser tube cutting machine through a local distributor. However, due to insufficient after-sales support, the machine had never been used to its full potential. Our technical team immediately stepped in, connected with the customer, and resolved the long-standing issue.

While working together to bring the machine back into optimal condition, the customer’s attention was quickly drawn to our newly upgraded high-speed laser tube cutting machine—the ST-FL80F Pro. Its high-speed cutting performance, fully automatic loading and unloading system, and exceptional material-saving capabilities left a strong impression.

Recognizing the customer’s production needs, we proposed a complete solution combining laser tube cutting and robotic welding specifically designed for the furniture manufacturing process. It happened to be the perfect timing—our March promotional event was underway. After reviewing the technical and cost advantages, the customer decided to place the order.

Once the equipment arrived at the Istanbul facility, our technical team continued to support the customer with online installation guidance, calibration assistance, and operational training.

By October, when our team visited the customer in Turkey, we were delighted to see the machines running smoothly - and even more delighted to see how confidently their team was now operating them.

Looking ahead, we are committed to delivering even more advanced, complete, and localized automation solutions to furniture manufacturers across Turkey - helping them upgrade production and achieve long-term competitiveness.

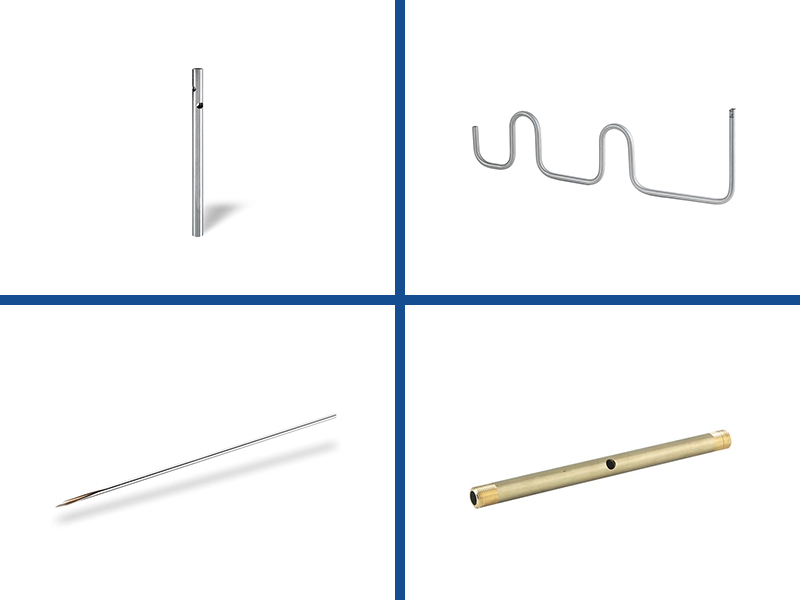

In the heart of Germany's renowned metalworking industry, precision isn't just a goal—it's a tradition. So, when a specialist in high-quality tubular components needed a laser tube cutter for exceptionally small diameters, the challenge was significant. They needed more than a machine; they needed a partner who understood the nuances of their craft.

In this Year, our team not only just send a quote, but also visited customer’s factory. We walked the production floor, saw their workflow, and listened to their ambitions. The goal was clear: flawless cuts on small tubes, maximum uptime, and intuitive operation and meet German Safety Regulation.

After details discussion and we know each other clearly, we offer them 3KW Small Tube Laser Cutting Machine to meet their high requirements.

This wasn't a one-size-fits-all proposal. It was a tailored answer. It delivers astonishing speed and clean, burr-free cuts on small diameters where precision is paramount. For our German client, this meant eliminating secondary finishing, boosting productivity, and expanding their design possibilities for intricate components.

Let's talk with SteviS about your specific needs. Discover how our targeted solutions can bring a new level of precision and efficiency to your workshop.

E: info@stevistech.com

service@stevistech.com (service)