Since 2008, Serves 8,000+ global clients, including renowned brands like SpaceX, NVIDIA, IKEA, and BYD

In 2024, a German stainless steel manufacturer faced a challenge: sourcing a laser tube cutting machine that matched their exacting standards. Safety compliance, material handling efficiency, and precision were non-negotiable. Here’s how we turned their vision into reality.

The Challenge

Located in Germany’s industrial heartland, the client needed a machine to process long stainless steel tubes (8m loading/6m unloading) while meeting strict EU safety protocols. As first-time importers of Chinese machinery, they sought reliability and seamless support.

Our Solution

*Custom-Built Excellence*

We engineered a dual-length laser cutting system tailored to their workflow, integrating advanced safety sensors and ergonomic material handling. The result? 20% faster cycle times compared to their existing setup.

*Borderless Support*

From factory acceptance testing to real-time shipping updates, we maintained full transparency. When customs complexities arose, our team worked overtime to help customers solve problems within 48 hours.

*Hands-On Partnership*

Our engineers are currently onsite in Germany, ensuring smooth installation and operator training.

Why Global Clients Choose Us?

1)EU-Certified Safety:All machines include CE-marked protective enclosures and emergency stop systems

2)Length Mastery: Handle tubes from 1m to 12m with our modular designs

3)360° Support: Multilingual technical assistance, the warranty is 1 year for whole machine, 2 years for laser source, lifetime technical support from SteviS. parts airlift.

Your Turn to Innovate

Whether you’re upgrading production or entering new markets, our laser solutions adapt to your requirements, not the other way around. The German client’s success story proves that quality knows no borders.

Background

A leading fitness equipment manufacturer based in Bulgaria was exploring ways to enhance the efficiency and precision of their production process. After observing that many industry peers had already integrated laser cutting technology for parts manufacturing, the company decided it was time to modernize its own operations.

Challenge

To identify a laser cutting solution that balanced both quality and affordability. The customer entrusted a trusted local distributor to find a reliable and cost-effective supplier that could meet their technical and financial requirements.

Solution

Through referrals from one of our long-standing clients in the region, the distributor discovered SteviS. After a thorough evaluation of our technology, manufacturing strength, and international service record, both the distributor and the end customer were impressed with the quality and performance of our machines.

Understanding the budget constraints of the client, our engineering team tailored a highly efficient and economically feasible laser tube cutting solution that didn’t compromise on quality or core functionality.

Result

The machine was successfully delivered and installed at the client’s factory. The customer has since integrated the SteviS laser tube cutting machine into their production line and is now producing high-quality components with improved accuracy and speed.

Customer feedback

When a Bulgarian client referred us to a fellow furniture manufacturer, we knew it was an opportunity to build another strong partnership. The new prospect reached out via Alibaba, sharing their need to upgrade their production line.

Understanding their urgency, we quickly tailored a solution and invited them to visit our factory during their upcoming trip to China.

Seeing is believing - so we guided them through every step of our production process, from raw materials to final packaging. Transparency and expertise built instant trust.

By the end of the day, the client was convinced. They confirmed the order before leaving, and the deposit arrived shortly after. They finally purchase Tube Laser Cutting Machine, Sheet Laser Cutting Machine, CNC Bending Machine, Handheld Laser Welding Machine, etc.

But the real win? Before the first machine even shipped, they placed a second order - proving that reliability sparks long-term collaboration.

Why It Works:

1.Referral-Driven Trust–A satisfied client’s recommendation paved the way.

2. Factory Visit = Confidence–Hands-on exposure eliminated doubts.

3.Speed & Commitment–Same-day decisions and repeat orders speak louder than promises.

Machines in customer factory

Your Turn: Ready to transform your production line? Let’s turn your vision into reality—fast. Please contact us asap!

As a leader in professional refrigeration and commercial equipment manufacturing, P Group has an annual turnover exceeding $150 million and a production footprint of over 1.4 million sq. ft, P Company’s commitment to innovation and quality is unwavering.

Recently, the company took a bold step forward by integrating cutting-edge laser tube-cutting technology into its production lines—a move that underscores its vision for precision, efficiency, and scalability.

To meet the growing demand for high-quality products, P Company invested in two high speed laser tube-cutting machines—models ST-TP120 and ST-TP120E.

These systems were deployed on a newly established production line dedicated to shaping metal tubes, which form the structural backbone of P Company’s refrigeration cabinets, cold rooms, and display cases.

The TP series machines, renowned for their accuracy and speed, enable P Company to achieve flawless cuts on complex metal profiles, ensuring seamless assembly and enhanced durability of their products. Whether crafting stainless steel refrigerated cabinets or custom-designed cold rooms, the precision of laser-cut components aligns perfectly with P Company’s reputation for delivering "time-proven European technologies" through eco-friendly, reliable manufacturing processes.

A 14-day on-site installation and commissioning process, led by our expert engineers, ensured the ST-TP120 and ST-TP120E systems were fully optimized for P Company’s production requirements. From calibrating cutting parameters to training technical staff, our team prioritized minimizing downtime while maximizing operational efficiency.

P Company’s leadership praised the machines’ performance, highlighting their robust build quality, intuitive controls, and ability to handle high-volume orders without compromising precision.

Our customer specializes in road and bridge engineering, operating a modern production facility focused on manufacturing critical structural components for infrastructure projects. Their products include precision-cut pipes, profiles, and various metal sheets essential for heavy-duty construction tasks.

In early last year, the factory manager made an initial investment in laser cutting technology, installing 1 set of automatic loading and unloading 3-chuck laser cutting machine specifically for processing pipes and profiles. The immediate improvement in cutting precision, edge quality, and overall productivity was evident. The new technology significantly reduced secondary processing, streamlined workflow, and optimized material utilization.

Previously, the company relied on plasma cutting technology for their sheet metal cutting processes. While effective for basic requirements, plasma cutting consistently produced rough edges and inaccuracies, leading to increased post-processing labor and material waste.

Impressed by the exceptional performance and clear operational benefits, the factory manager decided to replace their existing plasma cutting equipment completely. Recognizing the clear advantages, including precision, efficiency, and cost-effectiveness, the company has fully transitioned to laser cutting solutions.

The Gantry Type Fiber Laser Cutting Machine, with 13 meters * 3 meters cutting area and 6KW fiber laser source, has been operational with remarkable results—cutting quality has improved dramatically, productivity has increased, and operational costs have decreased significantly.

Encouraged by these outcomes, the factory manager has recently placed an order for an additional 20KW fully-enclosed exchange-table laser cutting machine dedicated to sheet metal processing, aiming to further boost productivity, enhance safety standards, and maintain a competitive edge in the market.

The successful adoption of laser cutting technology not only demonstrates the company's commitment to innovation and excellence but also positions them as a leader in road and bridge engineering component manufacturing. Through continued investment in advanced manufacturing technologies, the company is well-prepared to meet future industry demands and achieve sustainable growth.

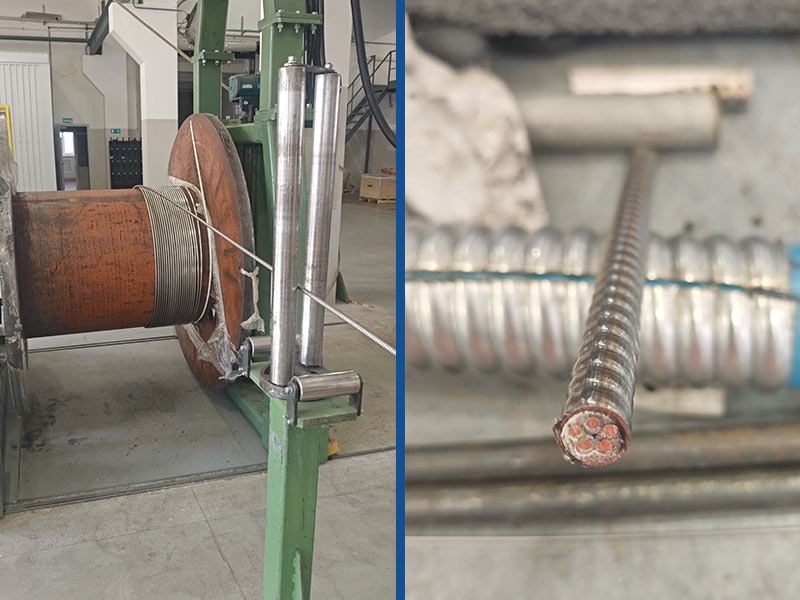

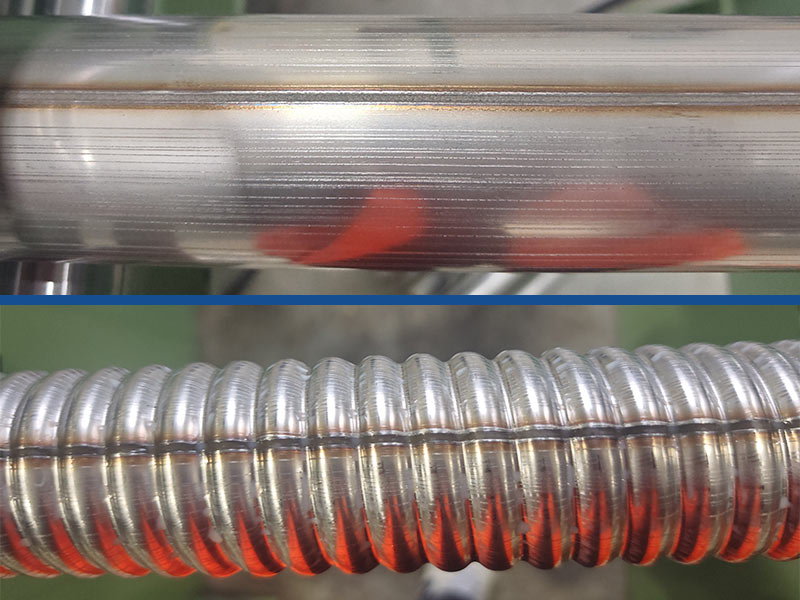

We are thrilled to announce our latest collaboration with Customer U, a leading Russian company in the cable industry. Customer U has recently acquired our state-of-the-art online laser welding machine to enhance their production capabilities.

Customer U discovered SteviS Tech through our comprehensive website. Impressed by our ability to provide online laser welding solutions to another customer with NVIDIA project and backed by 17 years of industry experience, they recognized us as a reliable partner. Navigating our website, they easily found the information they needed and reached out to discuss their requirements in detail.

Our seamless communication process played a key role in securing this partnership. U company appreciated the absence of any language barriers and found our sales team to be professional and knowledgeable, answering all technical questions with expertise. The smooth, helpful, and thoughtful interactions made the decision to collaborate with us an easy one.

Our Online Laser Welding Machine is designed to deliver high-performance welding with unparalleled accuracy and speed. This technology will enable Customer U to streamline their production, speed up their production, and maintain their high standards of excellence.

Machine test video:

This partnership marks an exciting expansion into the Russian market, showcasing our commitment to providing cutting-edge solutions globally. At SteviS Tech, we are dedicated to supporting our clients with innovations that drive success.

We are proud to partner with U and look forward to seeing the remarkable results they will achieve with our equipment.

Stay tuned for more updates on our collaborations and advancements in online welding technology!

The increasing demand for efficiency and quality in manufacturing has driven many companies to adopt automated solutions. One of the most effective tools for achieving this is the industrial welding robot workstation. In this case study, we will explore how a leading outdoor furniture manufacturer in China successfully integrated welding robot workstations to enhance productivity and maintain high-quality standards.

The client is a prominent outdoor furniture manufacturer based in China, specializing in a wide range of products, including outdoor furniture, cast aluminum tables and chairs, composite wood furniture, and Starbucks-style seating. The company operates on a sprawling site of over 100,000 square meters, with a skilled team of production technicians and advanced machinery, including large-scale die-casting equipment and die-casting molds. An in-house electrostatic powder coating production line enables the complete processing of raw materials, polishing, welding, grinding, and packaging within the factory premises.

In recent years, the company faced increasing labor costs, particularly in the welding process. To stay competitive in the market, the client needed to transition from manual welding to automated systems. Given the company’s location in a major production and machinery hub, they decided to explore local solutions for automation.

To address the client’s needs, we developed a customized industrial welding robot workstation specifically designed for aluminum furniture welding. Due to the high production volume of the client’s main products, our engineering team visited the factory to conduct a thorough analysis of the existing production processes. After gathering insights, we designed dedicated welding robot workstation solutions tailored to each major product line. This approach ensured that the automation system seamlessly fit into the client’s production workflow.

The implementation of the industrial welding robot workstation led to significant improvements in production efficiency. The automated process reduced manual labor while ensuring consistent and high-quality output. Consequently, the client’s products now meet European and North American quality standards, significantly boosting their appeal in these markets. By incorporating automated welding technology, the client not only reduced costs but also strengthened their position in the global outdoor furniture industry.

This case study demonstrates how a well-designed industrial welding robot workstation can revolutionize manufacturing processes, especially for companies facing rising labor costs. By adopting automated solutions, the client was able to enhance efficiency, maintain product quality, and increase their competitiveness in the international market. This success story highlights the crucial role of automation in modern industrial production.

J Group is World's major Bus and Electric Vehicle Manufacturer in India, sought to enhance production efficiency and product quality. This Group is also manufacturing thousand tons of high precision steel pipe raw materials per month.

This group sought to enhance production efficiency and product quality. The company aimed to replace its conventional flying saw of the tube mills with advanced laser cutting technology to achieve higher precision and productivity.

J Group faced a crucial decision in selecting the right supplier who could provide a comprehensive laser cutting solution tailored to their needs. After thorough market research and vendor evaluations, they discovered that we were the only supplier capable of offering a viable and effective solution.

Because they made the following requests:

| Material | Mild Steel / Carbon Steel |

| Outer Diameter | 25-95 mm |

| Wall Thickness | 0.8-4.5 mm |

| Cutting Length | 4-6.5 meters |

| Needs to meet Speed of Tube Mills | 30-50 meters/min |

The project officially commenced in September 2023. From the outset, both teams worked closely to establish clear project objectives and an effective implementation plan. Throughout this process, our engineers demonstrated exceptional professionalism and unwavering dedication. Through meticulous discussions and well-structured planning, every technical and operational aspect was carefully considered to ensure a seamless transition.

Machine test video:

By February 2024, the project successfully entered the execution phase, marking a significant milestone in our partnership. This achievement was made possible by the relentless efforts of every team member involved, as well as a shared commitment to precision and efficiency.

Machine running in customer factory:

The successful implementation of the laser cutting solution has significantly improved the manufacturer’s production process. The transition not only enhanced cutting precision but also optimized operational efficiency, resulting in reduced material waste and increased throughput. This success story is a testament to the power of collaboration, strategic planning, and technical expertise in driving industrial innovation.

The completion of this project underscores our commitment to delivering tailored, high-quality solutions that meet the evolving demands of the manufacturing industry. We take immense pride in contributing to our customer’s growth and operational excellence, and we look forward to continuing this successful collaboration in the future.

We are thrilled to announce our latest collaboration with R company, a leading Turkish company in the HVAC industry. R company has recently acquired our state-of-the-art CNC automatic metal circular saw-cutting machine to enhance their production capabilities.

R company discovered SteviS Tech through our comprehensive website. Impressed by our ability to provide complete metal processing solutions and backed by 16 years of industry experience, they recognized us as a reliable partner. Navigating our website, they easily found the information they needed and reached out to discuss their requirements in detail.

Our seamless communication process played a key role in securing this partnership. R company appreciated the absence of any language barriers and found our sales team to be professional and knowledgeable, answering all technical questions with expertise. The smooth, helpful, and thoughtful interactions made the decision to collaborate with us an easy one.

Our CNC automatic metal circular saw-cutting machine is designed to deliver high-performance cutting with unparalleled accuracy and speed. This technology will enable R company to streamline their production, reduce waste, and maintain their high standards of excellence.

This partnership marks an exciting expansion into the Turkish market, showcasing our commitment to providing cutting-edge solutions globally. At SteviS Tech, we are dedicated to supporting our clients with innovations that drive success.

We are proud to partner with R and look forward to seeing the remarkable results they will achieve with our equipment.

Stay tuned for more updates on our collaborations and advancements in cutting technology!

Related products

Headquartered in Singapore with a manufacturing plant in Malaysia, Customer L is a leading enterprise in steel structures and metal building materials processing.

They specialize in prefabricated steel structure engineering, with their products widely used in commercial complexes and educational buildings.

Initially relying on multiple punch presses for processing, the company faced increasing demands for higher quality and faster delivery as their business expanded.

The limitations of traditional methods prompted them to explore advanced laser technology, despite the significant initial investment.

To meet these demands, we provided a 6000W heavy-duty laser tube cutting machine. This technology promised to eliminate the recurring costs of punch press molds, making it a valuable long-term investment.

The client prioritized this project, personally overseeing the equipment acceptance and ensuring their engineers received comprehensive training.

Upon the machine's arrival at the Malaysian factory, our after-sales engineers were on-site the next day. They conducted installation, calibration, and maintenance training for the client’s technical team, ensuring a seamless transition to the new technology.

The adoption of laser technology has significantly enhanced the company's production efficiency and product quality, positioning them to better meet the demands of their expanding market.

In the future, the customer will consider adding 2-4 sets of heavy-duty metal fiber laser cutting machines to replace all the punching presses in the factory.

In addition, the customer also discussed with us the feasibility of the pipeline welding automation solution.

Related products

E: info@stevistech.com

service@stevistech.com (service)